|

|

|

|

|

|

|

|

|

Yarn Production

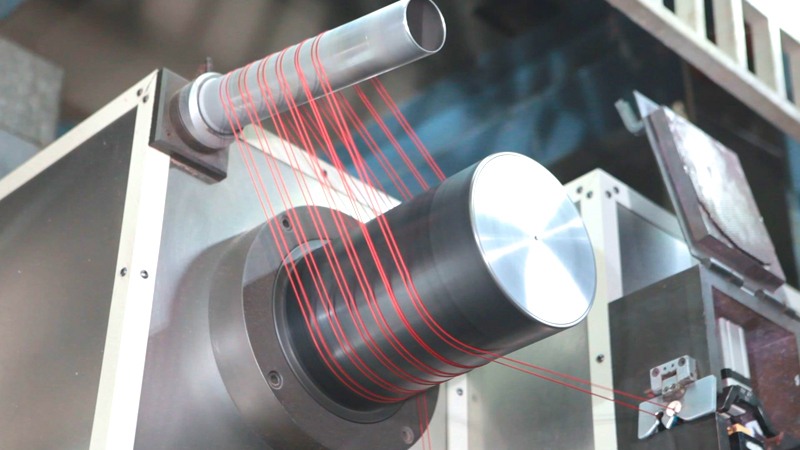

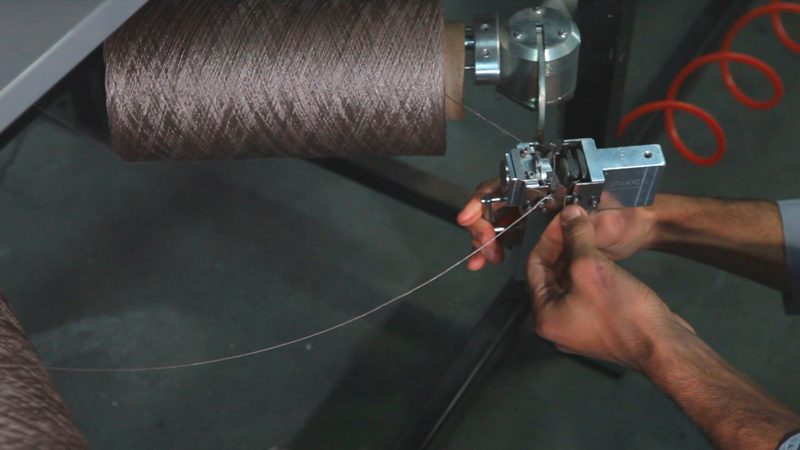

The Polypropylene Polymer cab be extracted using different additives ıf requested by client (anti-statics, colourings, UV stabilisers… etc.) and filtered to produce many strands. Once cooled, the strands are grouped together and stretched to achieve oriented strands. The end result is a bulky continuous filament yarn ( bcf ) with tenacity and stretching properties suitable for each procedure. To achieve the ideal colour stability and fastness, Frm Textile Yarn is manufactured by the method of spun dyed by adding a colour master-batch in the amounts need for the different shades. Lastly, once the Polpropylene Yarn is spun and wound, it will go through the twisting process to enable it to be processed into a textile , after twisting process in accordence with customer’s demand it can be heat – set or heat set friesed . All stages of manufacture are subject to rigorous controls in line . Furthermore, we continuously study new optimisation techniques and we are always up-to-date with the latest technology in our machines. In this way, our clients will always have the best quality and innovative yarns. We also have an R&D budget to invest for nev developments and diverse products that is now inevitable for carpet sector. |

Why Polypropylene ?

Polipropilen is very light material when compared with other fibers ( specific gravity of polypropylene is 0.90 gr/cc this value is 1.38 for polyester , 1.52 for viscose (rayon) , 1.54 for cotton , 1.57 for flax (linen) 1.31 for wool , 1.13 for nylon , 1.17 for acrylic and 1.33 for silk )

This means that covereing power of pp is highest amoung all fibers that enables manifacturers to get much more bulky effect when using pp .

Polypropylene is very resistant to acids , alkalines .

Mildews , fungus and bacteries can not penetrate or live in polypropylene that makes it very suitable yarn for carpet application.

Due to its very low moisture and water absorbancy ( %0,05) Polypropylene is hygienic fiber and prevents the material from generation of bacteries and microorganisms.

Applications

The flexibility, tenacity, chemical resistance, colour fastness and abrasion properties of the Polypropylene Yarn make it particularly suitable for a multitude of applications.

Carpet pile yarn

polypropylene bulk continuous filament yarn ( pp bcf ) in the form of monocolor or multicolor is best option as carpet pile yarn depending on customer demand it may be mingled , twisted & heat set , twisted & het set friesed .

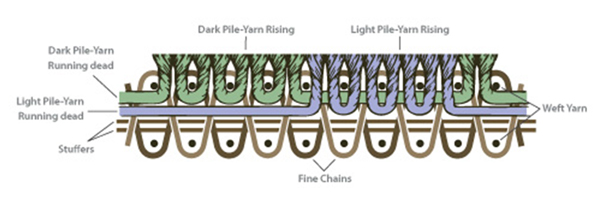

Wilton carpet weave configuration

|

|

|

|

pp yarns for short pile carpets |

pp yarns for shaggy carpets |

pp yarns for sisal carpets |

Tape

Sports, industrial, military, flexible containers or slings.

Ropes

Geotextile, industrial upholstery fabric, sports and travel equipment, rugs and carpets, filters, cloths, fabrics for the home, mattresses, blankets and garden furniture.

Sewing

Sewing yarn for industrial products, belts, etc…

Miscellaneous

nets, sacks, sheets, parasols, etc..

Products for medical usage

Filtration

Geotextile

Agrotextiles

Industrial tape:

Rope

Nets:

– Construction (laminated)

– Fishing

– Vehicle

– Sports

Sewing yarn

And many other uses …